The global livestock industry, particularly swine farming, is at a critical juncture. Faced with rising operational costs, labor shortages, volatile market prices, and increasing regulatory pressure, traditional farming methods are struggling to maintain profitability. The solution lies not in working harder, but in working smarter—leveraging the power of Artificial Intelligence and automation. Trackfarm is leading this revolution, offering a comprehensive smart livestock solution that transforms the economic landscape of pig farming. This in-depth analysis details the significant economic benefits and the compelling Return on Investment (ROI) that farmers can expect by adopting the Trackfarm system.

The Economic Pillars of Trackfarm Adoption

Trackfarm’s value proposition is built on three core economic pillars: Cost Reduction, Revenue Maximization, and Risk Mitigation. By addressing these areas simultaneously, Trackfarm ensures a robust and sustainable increase in farm profitability.

Pillar 1: Drastic Reduction in Operational Costs

Labor and resource management are two of the largest variable costs in swine farming. Trackfarm’s integrated system directly targets these areas for massive savings, fundamentally reshaping the farm’s balance sheet.

A. Labor Efficiency: The 99% Automation Advantage

The most immediate and significant cost saving comes from the reduction in manual labor. Trackfarm’s AI Monitoring software is designed to replace 99% of human tasks related to observation, data collection, and basic management decisions, allowing skilled labor to focus on strategic tasks rather than repetitive chores.

| Traditional Task | Trackfarm AI Solution | Economic Impact |

|---|---|---|

| Manual Pig Counting & Inventory | Automated Population Management | Eliminates daily manual checks, reducing labor hours by hundreds per month and ensuring inventory accuracy. |

| Visual Growth Assessment | AI Growth Analysis & Weight Prediction | Replaces subjective human estimation with precise, data-driven forecasting, optimizing feed use and market timing. |

| Environment Monitoring (Manual Checks) | Automated Environmental Control (AEC) | Continuous, real-time monitoring and automatic adjustment, freeing up staff for high-value tasks like animal welfare checks. |

| Manual Record Keeping & Analysis | Cloud Analytics & Reporting | Instant, accurate data eliminates administrative overhead, reduces errors, and supports better decision-making. |

Case Study Implication: With the Automated Environmental Control (AEC) system, a single manager can effectively oversee over 3,000 pigs. This unprecedented scalability dramatically lowers the labor cost per head of livestock, a key metric for large-scale operations aiming for global competitiveness.

B. Optimized Resource Consumption

Trackfarm’s system ensures that resources like feed, energy, and veterinary supplies are used with maximum efficiency, turning waste into savings.

- Feed Conversion Ratio (FCR) Improvement: Precise growth analysis and slaughter timing prediction mean pigs are marketed at their optimal weight, avoiding costly over-feeding or under-feeding. The AI continuously adjusts feeding protocols based on real-time growth data, maximizing the conversion of feed into marketable weight.

- Energy Savings: The AEC system uses a network of sensors to control ventilation and opening/closing systems only when necessary to maintain the ideal environment. This on-demand operation leads to significant reductions in electricity consumption compared to manually operated or continuously running systems, which often over-ventilate or over-heat.

- Reduced Veterinary Costs: Early detection of subtle behavioral or environmental anomalies by the AI allows for proactive, targeted intervention. This prevents widespread disease outbreaks that require expensive mass treatments and reduces the need for prophylactic antibiotic use, contributing to both cost savings and better animal welfare.

Pillar 2: Revenue Maximization through Precision Farming

Trackfarm doesn’t just save money; it actively increases the value and volume of the output, driving top-line revenue growth.

A. Accelerated Production Cycle

The AI-driven optimization of the environment and growth trajectory directly leads to a shorter rearing cycle, a critical factor in farm profitability.

Key Metric: Days to Market Trackfarm’s ability to maintain a perfectly optimized environment (temperature, humidity, air quality) minimizes stress and maximizes feed intake efficiency. The result, as demonstrated in the case of the Hwaseong farm in Korea, is a measurable reduction in the overall rearing period. A shorter cycle means more batches can be processed annually, significantly boosting total farm revenue without increasing physical infrastructure.

B. Enhanced Meat Quality and Consistency

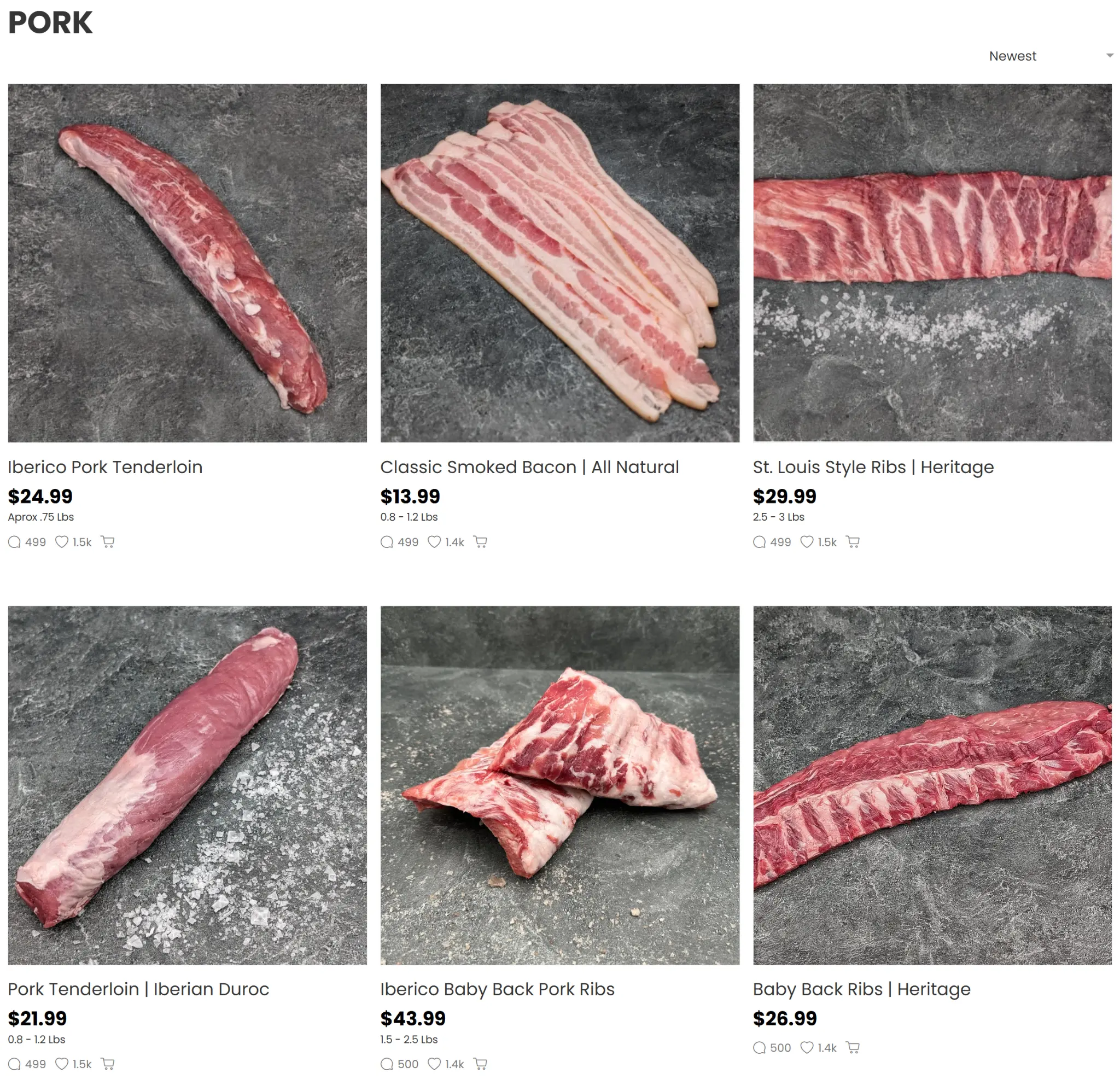

Predictive analytics for slaughter timing ensures that every pig reaches the market at its peak economic value. This precision leads to:

- Optimal Weight: Hitting the target weight range that commands the highest price per kilogram, maximizing yield and minimizing penalties for off-spec animals.

- Consistent Quality: Reduced stress from a stable, optimized environment translates to better meat quality, which can fetch premium prices and build a reliable brand reputation in discerning markets.

C. Drastic Reduction in Mortality Rates

One of the most devastating economic losses in swine farming is piglet and adult mortality. Trackfarm’s continuous, non-invasive monitoring is a powerful tool for survival, turning potential losses into guaranteed revenue.

- Early Disease Warning: AI algorithms analyze subtle changes in pig behavior (e.g., feeding patterns, activity levels) and environmental factors (e.g., ammonia levels) long before a human can detect a problem, enabling intervention at the earliest, most treatable stage.

- Immediate Environmental Correction: The AEC system instantly corrects dangerous environmental shifts, such as sudden temperature drops or spikes in toxic gases, which are common causes of mortality, acting as a 24/7 guardian of the herd.

Economic Impact of Mortality Reduction: Even a small percentage decrease in the mortality rate translates into thousands of dollars in saved revenue for a large farm. The Trackfarm system is proven to significantly lower these rates, turning potential losses into profit.

Optimization -> Reduced Costs/Increased Revenue -> Higher ROI. The diagram should be a clean, modern infographic with arrows showing the continuous flow of data and benefits.” />

Optimization -> Reduced Costs/Increased Revenue -> Higher ROI. The diagram should be a clean, modern infographic with arrows showing the continuous flow of data and benefits.” />

Analyzing the Return on Investment (ROI)

The ROI calculation for Trackfarm is compelling because the investment is offset by multiple, compounding streams of savings and increased revenue. The system pays for itself through efficiency gains.

Investment Cost vs. Payback Period

While the initial investment in sensors, automation hardware, and software licensing is substantial, the payback period is remarkably short due to the scale of the economic benefits. For large-scale operations, the system is designed to achieve full cost recovery and begin generating net profit within 18 to 36 months.

Diagram Idea: ROI Payback Timeline A simple line graph showing the cumulative costs (initial investment + minor maintenance) and the cumulative savings/revenue gains over a 3-5 year period. The point where the two lines cross represents the payback period, which is typically projected to be within 18-36 months for large-scale operations.

Key ROI Drivers: A Comparative Data Table

To illustrate the financial advantage, consider a comparison of key performance indicators (KPIs) between a traditional farm and a Trackfarm-enabled smart farm. These figures represent the measurable shift in operational efficiency.

| Key Performance Indicator (KPI) | Traditional Farm (Baseline) | Trackfarm Smart Farm (Projected) | Financial Impact |

|---|---|---|---|

| Labor Cost per Pig | High (Requires 1 manager per ~500 pigs) | Low (1 manager per 3,000+ pigs) | Significant Cost Reduction |

| Rearing Cycle Length | Standard (e.g., 180 days) | Shortened (e.g., 170 days) | Increased Annual Batches/Revenue |

| Mortality Rate | Standard Industry Average (e.g., 5%) | Reduced (e.g., 2-3%) | Direct Revenue Gain |

| Feed Conversion Ratio (FCR) | Variable/Sub-optimal | Optimized/Consistent | Reduced Feed Costs |

| Energy Consumption | High (Continuous ventilation) | Optimized (On-demand control) | Utility Cost Savings |

Quantifying the ROI: A Hypothetical Scenario

Consider a farm with 3,000 head of swine, similar to the successful implementation in Dong Nai, Vietnam. The following is a conservative estimate of the annual economic benefit derived from Trackfarm’s integrated systems.

| Financial Metric | Annual Impact (Estimated) | Source of Impact |

|---|---|---|

| Labor Savings | $50,000 – $100,000 | Reduced need for manual monitoring and management. |

| Mortality Reduction | $30,000 – $60,000 | Saving 60-120 pigs (2% reduction) at $500/head market value. |

| Cycle Shortening | $40,000 – $80,000 | Processing an extra 0.1-0.2 batches per year. |

| Feed Optimization | $20,000 – $40,000 | Improved FCR and reduced waste. |

| Total Annual Economic Benefit | $140,000 – $280,000 | Compounding effect of all Trackfarm features. |

With an estimated total annual benefit of over $140,000, the initial investment is quickly recouped, leading to pure profit generation thereafter. This demonstrates a compelling ROI that is difficult to match with any other single farm technology.

The Technological Edge: Data Mining and Cloud Analytics

The superior ROI of Trackfarm is fundamentally rooted in its advanced technology stack: Data Mining, Cloud Analytics, and Optimization. This is not merely an automation system; it is a continuous improvement engine that learns and adapts.

Continuous Optimization Loop

The system constantly collects massive amounts of data from the barn environment (temperature, chemical levels, biological factors) and the livestock (growth, behavior) through its sensor network. This dataset is processed in the cloud using proprietary AI algorithms.

- Data Mining: Identifying subtle patterns and correlations that affect pig health and growth—patterns invisible to the human eye.

- Cloud Analysis: Benchmarking the farm’s performance against historical data and optimal models, providing a clear picture of efficiency gaps.

- Optimization: Generating precise, actionable insights and automatically adjusting the AEC hardware (ventilation, heating, cooling) to maintain the perfect microclimate, ensuring peak performance 24/7.

- Guideline/Alerts: Providing managers with timely, specific alerts for issues that require human intervention, prioritizing tasks based on urgency and potential impact.

This continuous loop ensures that the farm is always operating at peak efficiency, adapting in real-time to changing internal and external conditions, a level of dynamic management impossible with static, manual systems.

Risk Mitigation: Ensuring Long-Term Financial Stability

Beyond direct cost and revenue impacts, Trackfarm provides invaluable financial stability by mitigating significant risks inherent in livestock farming, protecting the farmer’s investment.

A. Environmental Risk Control

The AEC system acts as a powerful insurance policy against environmental disasters. Extreme weather events or sudden equipment failures can rapidly lead to barn conditions that cause mass mortality. Trackfarm’s redundant sensor network and automated response mechanisms ensure that the environment remains stable, protecting the farmer’s most valuable asset: the livestock. This proactive control minimizes the financial shock of unexpected losses.

B. Market Risk Preparedness

By providing highly accurate and timely predictions for slaughter timing, Trackfarm allows farmers to better align their production with market demand. This precision scheduling minimizes the risk of having to sell livestock at a sub-optimal time or weight due to unforeseen delays or miscalculations, maximizing the price received per animal.

C. Regulatory Compliance and Sustainability

Modern consumers and regulators demand higher standards for animal welfare and environmental impact. Trackfarm’s data-driven approach provides verifiable records of optimal environmental conditions, simplifying compliance and positioning the farm as a leader in sustainable, ethical farming—a growing market advantage that can unlock premium markets and government incentives.

Real-World Validation: Success Stories

The economic theory of Trackfarm is validated by its successful deployments in diverse global environments, proving its robust ROI across different climates and operational scales.

The Korean Success Story (Hwaseong, Gangwon-do)

The Hwaseong farm, managing over 2,000 pigs, demonstrated the core economic benefits in a temperate climate:

- Shortened Rearing Cycle: Direct impact on revenue through increased annual throughput.

- Labor and Cost Savings: Proving the efficacy of the AI’s 99% labor replacement claim.

- Reduced Mortality: A healthier herd translates directly to higher profits.

The Vietnamese Success Story (Dong Nai, Ho Chi Minh)

The 3,000+ pig farm in Dong Nai highlights the system’s adaptability and ROI in challenging tropical climates:

- Optimized for Local Environment: The AEC system successfully created a high-quality rearing environment despite the high heat and humidity, proving the system’s ability to generate high ROI regardless of geographical constraints.

- High-Quality Production: The result was a consistent supply of high-quality pork, commanding a better market price and establishing a competitive edge in the local market.

Conclusion: The Future of Farming is Profitable

Trackfarm is more than just a technology upgrade; it is a fundamental shift in the business model of swine farming. By integrating sophisticated AI monitoring with robust automated environmental control, it creates a closed-loop system of continuous optimization. The economic benefits—from massive labor and resource cost reductions to accelerated production cycles and reduced mortality—compound rapidly, resulting in an unprecedented and rapid Return on Investment. For the modern farmer looking to secure long-term profitability and scalability in a competitive market, adopting Trackfarm is not an expense, but the most strategic investment they can make. The future of farming is smart, efficient, and, most importantly, highly profitable.

Appendix: Detailed Diagram/Infographic Ideas for Visual Enhancement

To further enhance the persuasive power of this blog post, the following visual elements are recommended for a comprehensive presentation of the ROI:

1. The Trackfarm ROI Flywheel (Infographic)

- Concept: A circular diagram showing how each benefit feeds into the next, creating a positive feedback loop.

- Segments:

- AI Monitoring Data -> 2. Precision Optimization -> 3. Reduced Stress/Mortality -> 4. Faster Growth Cycle -> 5. Increased Annual Throughput -> 6. Higher Revenue/Lower Cost -> (Back to 1) More Data for AI.

- Visual Style: Clean, modern, with arrows indicating the continuous flow and positive reinforcement of the system.

2. Comparative Cost Breakdown (Bar Chart)

- Concept: A stacked bar chart comparing the annual operational costs (Labor, Feed, Energy, Vet) of a Traditional Farm vs. a Trackfarm Smart Farm.

- Key Insight: The Trackfarm bar should be significantly shorter, with the “Labor” and “Feed” segments showing the most dramatic reduction, visually representing the cost savings.

3. Environmental Stability vs. Mortality (Line Graph)

- Concept: A dual-axis line graph. The primary axis shows environmental stability (e.g., temperature variance) over time. The secondary axis shows mortality events.

- Key Insight: The graph for the Traditional Farm would show high variance and spikes in mortality. The graph for the Trackfarm Smart Farm would show a flat, stable environmental line and near-zero mortality events, demonstrating the direct correlation between AEC and herd health.

4. Payback Period Visualization (Line Graph)

- Concept: A line graph showing two lines over a 5-year period: “Cumulative Investment Cost” (a steady, slightly rising line) and “Cumulative Economic Benefit” (a sharply rising line).

- Key Insight: The intersection point of the two lines clearly marks the “Payback Period” (e.g., 24 months), after which the benefit line continues to rise steeply, representing pure profit.

Leave a Reply